The history of Ceruse: First in Elizabethan cosmetics and later

as a wood finishing and preservation technique

In the 1500’s, originating as a beauty trend during the long reign of Elizabeth I, it was in fashion for the wealthy women of the day to have very light skin.

As a result, the French aristocrats started using a mercury paste on their skin to lighten their complexion. It was believed that the lighter your skin the less you had worked and therefore the more affluent you were. One can only imagine what that mercury did to their health!

Luckily, this beauty trend did not last long, however the ceruse process soon transferred to the furniture industry, where the white “look” given to interior furniture and millwork through the use of a lead paste and wax became quite popular.

This process was referred to as Liming, and later as Cerusing, and was not only prized for aesthetic reasons, but also served as a preservative – preventing future rot and insect damage to the wood.

Unfortunately, most of the early wood treatments were very toxic to the woodworkers who handled them. Today’s treatments are created with modern finishes and are nontoxic.

In terms of modern architecture and design, we mainly see cerused finishes on furniture and millwork as a nod to our Art Deco past. As with fashion and beauty trends, interior design is also cyclic. During the 1950’s ceruse finishes were sought after for their modern “elegant” appeal.

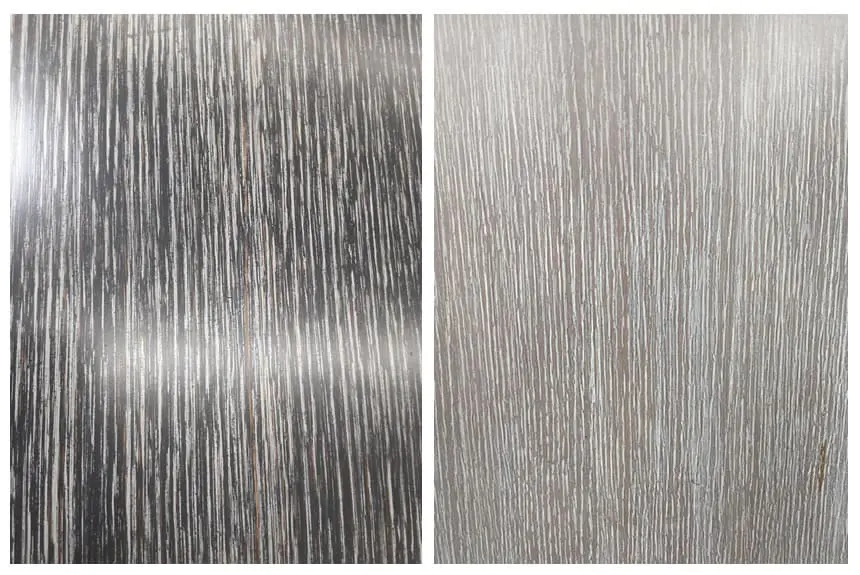

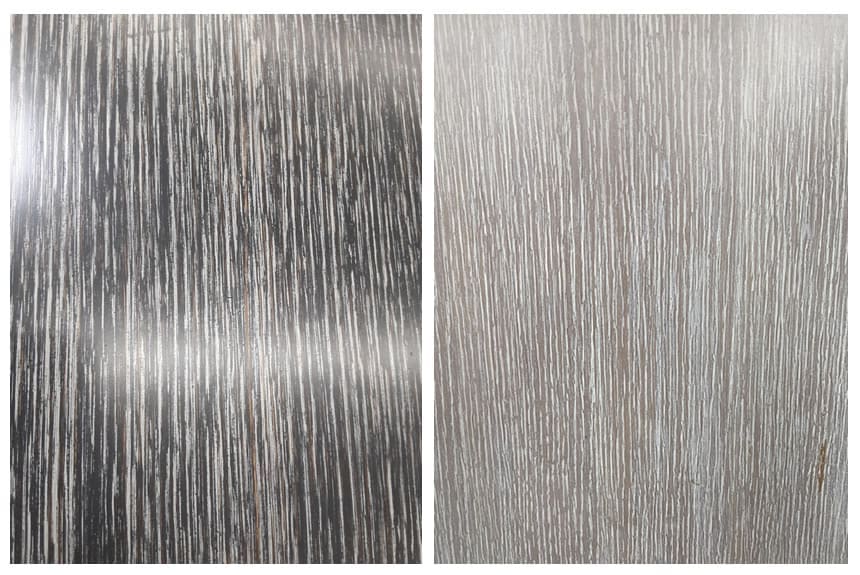

The ceruse process is most commonly performed on oak but also works well with other open grained species like ash and hickory. Wire brushing the straight grain of rift white oak tops today’s popularity list in 2022.

Many lumber and plywood suppliers offer their products with the wire brushing completed for you – giving the wood surface a consistent look. Once your cabinet or piece of furniture is built a base color is applied. This gets lightly sanded and prepped for the remaining steps in the process.

For all of your challenging finishing projects please contact Matt Squires, OFS Shop Manager, at 860-282-1041 or msquires@ofscorp.com